Butadadieno de acrilonitrila (ABS) é um polímero termoplástico amplamente utilizado conhecido por sua excelente resistência ao impacto, resistência, e facilidade de processamento. Devido a essas propriedades superiores, ABS é amplamente utilizado em várias indústrias, incluindo automotivo, médico, eletrônica de consumo, e eletrodomésticos. O ABS injection molding requer controle preciso sobre manuseio de material, temperatura, pressão, e resfriamento para garantir produtos moldados de alta qualidade. Este artigo cobrirá as etapas principais, práticas recomendadas, e soluções para o comum Defeitos de moldagem por ABS Para otimizar os resultados de fabricação.

What is ABS Plastic?

ABS is an engineering thermoplastic with a balance of strength, rigidity, and processability. Some of its key characteristics include:

- High impact resistance and toughness for durable products

- Good dimensional stability to maintain part accuracy

- Strong resistance to chemicals and heat

- Excellent surface finish and paintability

- Boas propriedades de isolamento elétrico, tornando -o ideal para componentes eletrônicos

Essas propriedades tornam o ABS ideal para a produção de peças automotivas, gabinetes eletrônicos, dispositivos médicos, e bens domésticos.

Processo de moldagem por injeção de ABS

ABS (Butadadieno de acrilonitrila) is a popular thermoplastic used in injection molding due to its excellent strength, resistência, and surface finish. Here’s an overview of the injection molding process specifically tailored for ABS material:

Machine Requirements

ABS can be molded using standard injection molding machines, but the following conditions are important to ensure optimal results:

-

Screw Type: General-purpose screw with a compression ratio of 2.5–3.0

-

Injection Pressure: Typically 70–120 MPa

-

Clamping Force: Medium to high, depending on part size and complexity

-

Drying Requirements: ABS must be dried at 80–90°C for at least 2–4 hours before processing to avoid moisture bubbles or silver streaks

Processing Temperature Range

Temperature control is critical when molding ABS, as it is sensitive to degradation if overheated.

| Zone | Recommended Temperature |

|---|---|

| Feed Zone | 190 – 210°C |

| Compression Zone | 210 – 230°C |

| Metering Zone | 220 – 250°C |

| Nozzle | 220 – 250°C |

| Mold Temperature | 60 – 80°C |

Maintaining stable and uniform temperature is essential to prevent warping, surface defects, and internal stress.

Injection Pressure & Speed

-

Injection Pressure: 70–120 MPa

-

Holding Pressure: 40–60% of injection pressure

-

Injection Speed: Medium to fast (slower speeds may cause weld lines; faster speeds can help achieve better surface finish)

Shrinkage

ABS has a relatively low shrinkage rate, typically between 0.4% – 0.7% depending on:

-

Espessura da parede

-

Mold design

-

Gate type and size

-

Fill rate and pressure

Proper cooling time and uniform mold temperature are crucial to minimize warping and ensure dimensional stability.

Advantages of ABS Injection Molding

ABS is a widely used engineering thermoplastic, especially popular in automotive, eletrônica de consumo, and medical device industries. Its combination of mechanical strength, aesthetic quality, and processing ease makes it ideal for injection molding.

1. High Impact Resistance

ABS offers excellent toughness and impact strength, making it suitable for parts that require durability under mechanical stress. This makes it ideal for products like:

-

Protective housings and enclosures

-

Automotive interior components

-

Handheld device cases

Even at low temperatures, ABS maintains impact resistance, making it reliable for both indoor and outdoor applications.

2. Excellent Surface Finish

One of ABS’s standout qualities is its smooth surface finish and good gloss. This allows molded parts to be:

-

Easily painted, banhado, or silk-screened

-

Used directly in consumer-facing applications without secondary processing

-

Made with intricate surface details (thanks to its good flow characteristics)

This is why ABS is often used in aesthetic components of electronics, such as remote controls or appliance panels.

3. Recyclability

ABS is a thermoplastic, meaning it can be melted down and reprocessed without significant degradation. Its recyclability offers:

-

Lower material costs through reuse of regrind

-

Reduced environmental impact

-

Easier waste management in high-volume production

Industries increasingly value ABS for sustainable manufacturing due to its recyclability and low VOC emissions.

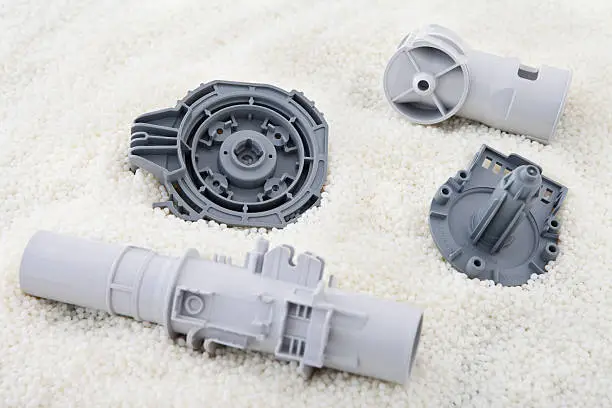

Aplicações de moldagem por injeção de ABS

A moldagem por injeção de ABS é amplamente utilizada em várias indústrias, incluindo:

- Indústria médica: Altas de equipamento, Componentes do dispositivo de diagnóstico

- Indústria automotiva: Painéis, Entendimentos internos, e componentes de pára -choques

- Eletrônica de consumo: Casos de laptop, quadros de teclado, e controles remotos

- Aparelhos domésticos: Peças a pó, forros de geladeira, e caixas de ferramentas

Optimal ABS Injection Molding Parameters

a. Temperature Settings

Proper temperature control ensures uniform melting and prevents molding defects.

- Barrel temperature: 200–250°C (392–482°F)

- Nozzle temperature: Slightly lower than barrel temperature to prevent drooling

- Temperatura do molde: 50–80°C (122–176°F), depending on part thickness

b. Injection Speed and Pressure

- Injection pressure: 10–20 MPa (1450–2900 psi)

- Holding pressure: 30–50% of the injection pressure

- Injection speed: Medium to high to ensure proper flow into the mold cavities

- Back pressure: 0.3–4 MPa to ensure uniform melting

c. Cooling Time and Ejection

- Cooling time: 20–60 seconds depending on part thickness

- Ejection system: ABS parts should be properly cooled before ejection to avoid deformation

Common ABS Molding Defects and Solutions

1. Bubbles or Silver Streaks

- Causa: Excess moisture in ABS material

- Solution: Ensure proper drying before processing

2. Burn Marks

- Causa: Superaquecimento devido à alta velocidade de injeção ou tempo prolongado

- Solution: Abaixe a temperatura do barril e ajuste a velocidade de injeção

3. Tiros curtos

- Causa: Pressão de injeção insuficiente ou baixa temperatura

- Solution: Aumentar a pressão da injeção e garantir a temperatura de fusão adequada

4. Piscando

- Causa: Pressão excessiva de injeção ou pingo de molde inadequado

- Solution: Otimize as configurações de pressão e verifique o alinhamento do molde

ABS Injection Molding at XLD Mould

No Molde xld, Estamos comprometidos em fornecer soluções de moldagem por injeção de ABS de alta precisão que atendem aos padrões mais exigentes do setor. Nossa experiência garante:

- Design de molde personalizado e engenharia para desempenho e eficiência aprimorados

- Orientação de seleção de material para garantir a funcionalidade e durabilidade ideais

- Otimização avançada do processo de moldagem por injeção para alcançar consistente, Resultados de alta qualidade

- Comprehensive defect prevention strategies to minimize waste and maximize productivity

With our state-of-the-art manufacturing capabilities and a dedicated team of experts, XLD Mould guarantees superior ABS injection molding services tailored to your specific needs.

📞 Entre em contato conosco hoje to discuss your ABS molding project and let us provide you with innovative, cost-effective injection molding solutions.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. Mas, I have a question, can you help me?

Yo, nexusgaming88com is on my radar. Gotta see what all the fuss is about. Wish me luck, maybe I’ll hit the jackpot!

Been having some fun with jjwinbet lately. It seems like a really trust worthy site, I can’t complain! jjwinbet

MNL168 online casino is where it’s at! Great selection of games – I’ve been having a blast trying them all out! Join me on mnl168onlinecasino and let’s hit the jackpot!

Hi, I do think this is an excellent blog. I stumbledupon it 😉 I will return once again since i have saved as a favorite it. Money and freedom is the greatest way to change, may you be rich and continue to help others.

Thank you for the auspicious writeup. It in fact was a amusement account it. Look advanced to more added agreeable from you! By the way, how can we communicate?

I really like reading through an article that will make men and women think. Também, thanks for permitting me to comment!

A person necessarily assist to make seriously posts I’d state. This is the first time I frequented your website page and up to now? I amazed with the analysis you made to make this actual post amazing. Magnificent process!

I love what you guys are up too. This sort of clever work and coverage! Keep up the superb works guys I’ve added you guys to our blogroll.

Greetings! Very useful advice in this particular post! It is the little changes that will make the biggest changes. Thanks for sharing!

I am sure this paragraph has touched all the internet viewers, its really really pleasant paragraph on building up new blog.

Yoou have madee soe decent poinmts there. I loooked onn tthe webb tto findd outt more abolut thee issue annd found mos people wiull goo along with your views oon thiss weeb site.

I am sure this paragraph has touched all the internet visitors, its really really fastidious paragraph on building up new webpage.

Ahaa, its fastidious conversation about this piece of writing here at this blog, I have read all that, so now me also commenting here.

This is a topic that is close to my heart… Thank you! Where are your contact details though?

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

**prodentim reviews**

ProDentim is a distinctive oral-care formula that pairs targeted probiotics with plant-based ingredients to encourage strong teeth, comfortable gums, and reliably fresh breath

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Real excellent information can be found on weblog.

It takes place when two opposing Pokemon inevitably cross each other’s paths on the board.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.info/register?ref=IXBIAFVY