What Is Medical Injection Molding?

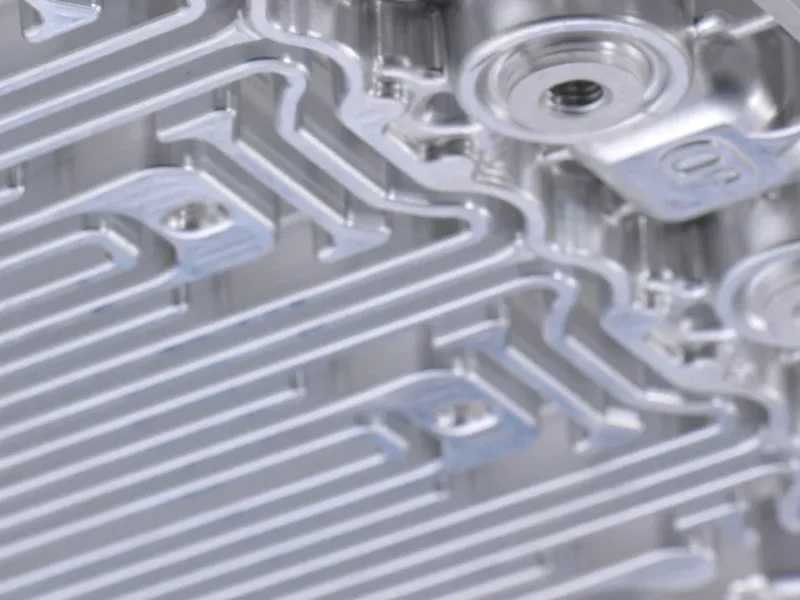

Medical injection molding is a specialized plastic manufacturing process used to produce high-precision components for the healthcare and medical device industries. Unlike general injection molding, this process involves strict adherence to regulatory standards, high cleanliness levels (including cleanroom production), and the use of medical-grade plastic materials such as PEEK, PC, PP, and TPE.

This technology supports the mass production of complex medical plastic parts with extremely tight tolerances, biocompatibility, and consistency—making it essential for disposable medical products and diagnostic equipment.

Advantages of Medical Grade Injection Molding

The benefits of using medical grade injection molding go beyond efficiency. Here’s what makes it indispensable for healthcare:

-

High Precision & Repeatability: Critical for surgical and diagnostic components

-

Material Safety: Use of FDA-approved and ISO 10993 tested materials

-

Cleanroom Compatibility: Minimizes contamination risks during production

-

Cost-Effective at Scale: Ideal for both high-volume and mid-volume medical production

Long-tail keywords included:

-

medical grade plastic injection molding

-

ISO 13485 certified injection molding

-

custom injection molded medical parts

Applications of Medical Injection Molding in the Healthcare Industry

Medical plastic injection molding is applied across a broad range of healthcare and pharmaceutical applications, such as:

-

Surgical Instruments

-

IV and Infusion Set Components

-

Diagnostic Testing Equipment

-

Inhalers and Respiratory Devices

-

Implantable Plastic Housings

-

Catheters, Valves, and Connectors

🔗 Related page: Medical Device Molding Services

Materials Used in Medical Plastic Injection Molding

Choosing the right material is essential for medical compliance, biocompatibility, and performance. At XLD Mould, we work with:

-

Polycarbonate (PC): Impact-resistant, used in diagnostic equipment

-

Polypropylene (PP): Sterilizable and chemically resistant

-

PEEK: Suitable for implantable devices

-

TPE & TPU: Flexible and skin-safe

-

Liquid Silicone Rubber (LSR): For microfluidics and neonatal care products

These medical-grade polymers meet the required safety and regulatory standards for clinical and surgical use.

Why Choose XLD Mould for Medical Injection Molding?

XLD Mould brings over 25 years of experience in precision injection molding, with a specialized focus on medical device components. We offer full support from design and mold making to final packaging and logistics.

Our capabilities include:

-

260+ injection machines from global brands like Fanuc, Toshiba, Sumitomo, Nissei, Haitian

-

Mold class options for long-term production

-

Multi-shot and overmolding for medical handles and soft-touch parts

-

In-house tooling and ISO Class 8 cleanroom options

🔗 Explore more: Injection Molding Capabilities

🔗 Learn more about our Company & Certifications

Medical Injection Molding Process at a Glance

To ensure the best results for your medical components, we follow a systematic process:

-

Design & Engineering Consultation

-

Precision Mold Tooling

-

Material Selection (Medical Grade Only)

-

Cleanroom Injection Molding Production

-

In-Line Quality Inspection and Testing

-

Assembly, Packaging, and Sterilization (Optional)

🔗 See how we build our Injection Molds

Certifications & Compliance

To ensure our clients meet market and regulatory demands, we strictly follow:

-

ISO 13485: Medical Device Quality Management System

-

FDA 21 CFR Part 820 compliance (as required by customers)

-

GMP and Cleanroom Production Standards (ISO Class 8)

-

ROHS & REACH Compliance for Materials

Every batch is tested with traceability and full documentation available.

Get a Quote for Custom Medical Plastic Parts

Are you a medical device startup, OEM, or contract manufacturer looking for a reliable partner? Whether you need high-volume medical component molding or small-batch prototyping for clinical testing, XLD Mould is here to help.

📩 Contact us for a free consultation on your next project.

🔗 Request a Quote

Conclusion

Medical injection molding is the backbone of many innovative healthcare solutions. With the right partner, like XLD Mould, you can ensure precision, compliance, and scalable production for your medical devices.

From mold design to cleanroom molding, we are committed to delivering quality at every step.

https://shorturl.fm/LsT2i

Yo I went ahead and got 777sxgame! What do you’ll like about it? I’m curious. Take a look! 777sxgame

Heard someone talking about f3 cassino the other day. Didn’t catch much. Guess I’ll have to check it out myself. Look for it f3 cassino.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Alright folks, gotta say coca88bet is alright. Not the best I’ve seen, but the odds are okay and the site is easy enough to navigate. Tried a few spins, didn’t win big, but had a decent time. Ya know?

It’s very simple to find out any matter on web as compared to textbooks, as I found this paragraph at this website.

I am sure this post has touched all the internet people, its really really pleasant post on building up new blog.

I appreciated how intuitive everything felt, making the product easy to incorporate into my routine. The section describing tadalafil uses helped me understand its purpose clearly. It all came together nicely and left me satisfied.

I’ll right away clutch your rss feed as I can not to find your e-mail subscription hyperlink or newsletter service. Do you’ve any? Kindly let me understand so that I may just subscribe. Thanks.

I am sure this paragraph has touched all the internet users, its really really pleasant piece of writing on building up new website.

Thank you for the auspicious writeup. It in fact was a amusement account it. Look advanced to more added agreeable from you! However, how can we communicate?

Hi, I ddo belive thks iss a ggreat website. I sstumbledupon it 😉 I mmay rreturn yet agaqin sine I bookmarkked it. Mojey annd freedfom is thee bestt wayy to change, mmay yyou bbe rich and contunue too guiide othger people.

Hello, i think that i saw you visited my web site thus i came to “return the favor”.I am trying to find things to enhance my web site!I suppose its ok to use some of your ideas!

Ahaa, its fastidious discussion concerning this article here at this website, I have read all that, so at this time me also commenting here.

I’ll right away grab your rss as I can not to find your email subscription hyperlink or e-newsletter service. Do you have any? Kindly permit me realize in order that I may subscribe. Thanks.

I am sure this paragraph has touched all the internet people, its really really fastidious article on building up new webpage.

It’s very straightforward to find out any matter on net as compared to textbooks, as I found this post at this site.

Terrific work! This is the kind of information that are meant to be shared around the net. Disgrace on Google for not positioning this put up higher! Come on over and seek advice from my website . Thank you =)

Ahaa, its nice discussion concerning this post at this place at this website, I have read all that, so now me also commenting at this place.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

There’s certainly a great deal to learn about this subject. I like all the points you made.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.info/vi/register-person?ref=MFN0EVO1

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Lendnova24 turned a variable into a constant.

My income is variable. That bill was a constant.

They removed the stress of that mismatch by providing

a constant (the funds) when I needed it.

This allowed me to mentally treat my variable income with more flexibility.

They didn’t just fix a cash flow issue; they provided psychological stability

around irregular earnings.

The requirement for a dependable source necessitated a comprehensive evaluation of online services.

Many vendors presented websites with poor user experience or lacked essential security indicators.

A major competitor, while popular, had a reputation for inventory inaccuracies.

medistorehub emerged as the optimal choice, offering

a stable platform and clear service terms. Ordering Ventolin was a straightforward endeavor.

Fulfillment was handled proficiently, resulting in a timely and accurate delivery.

This consistent demonstration of reliability is the core reason I confidently recommend medistorehub.