|

Product Description

|

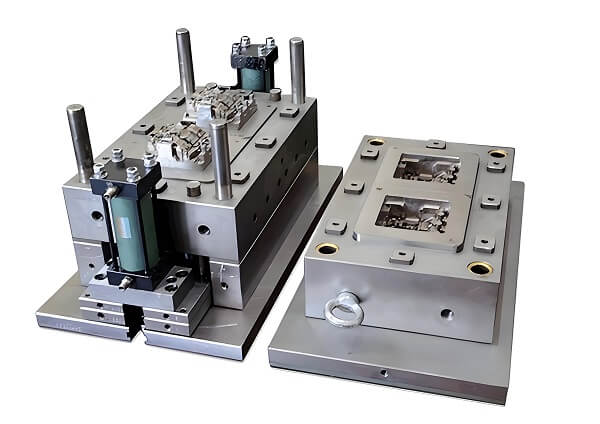

ODM plastic injection molding

|

|

Plastic Materials:

|

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,…etc.

|

|

Standard:

|

ISO9001:2008

|

|

Other materials:

|

Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper…Metal…etc.

|

|

Quality:

|

RoSH and SGS standard

|

|

Feature:

|

Non marking and Non flash

|

|

Size:

|

According to your 2D, 3D Drawing

|

|

Color,Quantity,Unit price,Tooling cost,Tooling size:

|

To be discussed

|

|

Package:

|

Standard exported Wooden box packed, Fumigation process(upon required)

|

|

Mold Building Lead Time:

|

T1, 4-5 weeks, Part measurement report (upon required).

|

|

Export Country:

|

Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy…etc.:

|

|

Experience:

|

13 years experience in plastic injection mold making and plastic prouducts produce.

|

|

To be discussed

|

In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,…etc.

|

|

Mould Base:

|

Hasco Standard, European Standard, World Standard

|

|

Mould Base Material:

|

LKM, FUTA, HASCO, DME,…etc. Or as per Customer’s Requirment.

|

|

Surface Finish:

|

Texture(MT standard), High gloss polishing

|

|

Cavity/Core Steel:

|

P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 …etc.

|

|

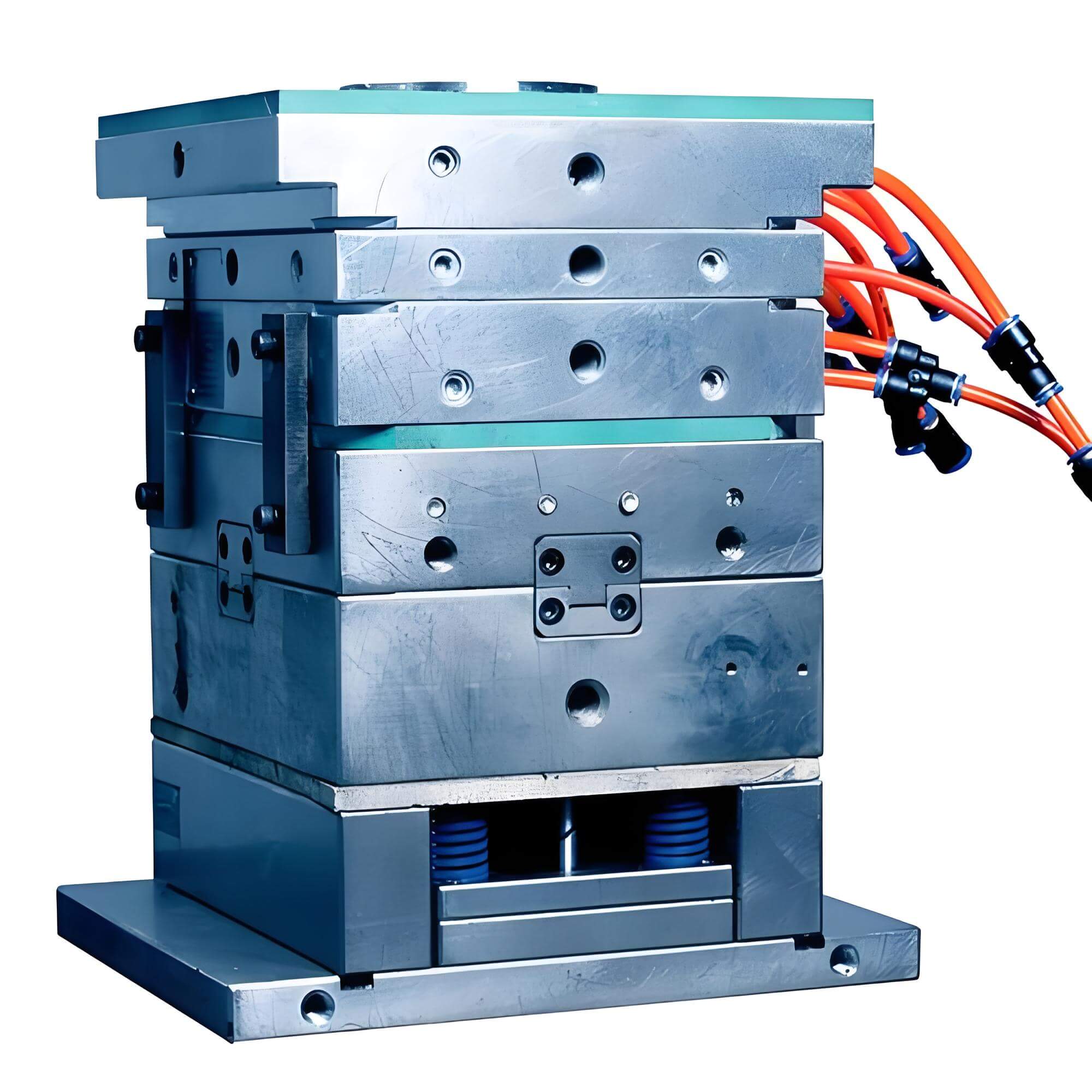

Hot/ Cold Runner

|

HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc.

|

|

Mould Life:

|

5,000 to 1,000,000 Shots. (According to your working environment.)

|

|

Design & Program Softwares:

|

CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA….etc.

|

At GHXLD Precision Mould Co., Ltd., we are a leading professional plastic injection mould manufacturer, providing high-quality, customized moulding solutions for a wide range of industries. With years of expertise, we design and manufacture precision injection moulds for various applications including automotive, electronics, packaging, medical, and consumer goods.

Key Features:

- Custom Solutions: Tailored injection moulds to meet the unique needs of your products, ensuring perfect fit and functionality.

- Precision Engineering: Our moulds are engineered with the highest level of precision, ensuring durability and optimal performance for high-volume production.

- Wide Range of Industries: Serving industries such as automotive, electronics, medical, consumer goods, packaging, and more.

- Advanced Technology: We use the latest injection moulding technologies and CAD/CAM systems to create high-quality, efficient moulds.

- Material Expertise: We work with a variety of materials including ABS, PP, PE, PS, PC, and more to meet the specific requirements of each project.

- Quick Turnaround: Fast and efficient production to meet deadlines, from prototyping to mass production.

- Competitive Pricing: Offering cost-effective solutions without compromising on quality, helping you maximize profitability.

Why Choose Us?

- Experienced Team: Our skilled engineers and technicians ensure high-quality designs and optimal manufacturing processes.

- Quality Assurance: We conduct rigorous testing and quality checks to ensure the durability and precision of every mould.

- Customer Satisfaction: We focus on delivering results that exceed customer expectations, with personalized service and support.

Let us help you create reliable, high-quality plastic products with our custom plastic injection moulding solutions. Contact us today to discuss your next project!

Reviews

There are no reviews yet.