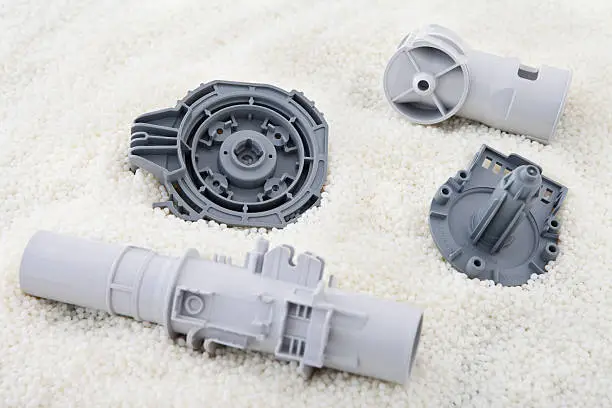

Ko te Acrylonitrile Butadiene Styrene (Akonga) Ko te polymer thermoplastic nui e mohiotia ana mo tana tohe kaha, taikaha, me te ngawari o te tukatuka. Na enei ahuatanga tino pai, Kei te whakamahia whānuitia abs i roto i nga momo ahumahi, Whakauru atu, hauora, Hipanga Kaihoko, me nga taputapu whare. Te ABS injection molding me whai mana te mana whakahaere i nga taonga, pāmahana, pēhanga, me te whakamahana kia pai ai te whakarite i nga hua hanga kounga nui. Ka kapi tenei tuhinga i nga waahanga matua, Nga mahi pai, me nga otinga hei noa Nga ngoikoretanga abs ki te whakatika i nga hua hangahanga.

What is ABS Plastic?

Ko te abs he miihini miihini me te toenga o te kaha, rigidity, me te poka. Ko etahi o ona tohu nui kei roto:

- Te kaha o te tohetohe me te uaua ki nga hua pumau

- Te nuinga o te pumau ki te pupuri i te tika

- Te kaha o te ātete ki te matū me te wera

- Te mutunga o te mata pai me te peita

- Ko nga taonga whakangao hiko pai, He pai ki te hanga i nga waahanga hiko

Ko enei taonga ka whai hua ki te whakaputa i nga waahanga miihini, Papa hiko, Nga taputapu rongoa, me nga taonga o te whare.

Te mahi whakahiato a te Abs

Akonga (Ko te Acrylonitrile Butadiene Styrene) is a popular thermoplastic used in injection molding due to its excellent strength, taikaha, and surface finish. Here’s an overview of the injection molding process specifically tailored for ABS material:

Machine Requirements

ABS can be molded using standard injection molding machines, but the following conditions are important to ensure optimal results:

-

Screw Type: General-purpose screw with a compression ratio of 2.5–3.0

-

Injection Pressure: Typically 70–120 MPa

-

Clamping Force: Medium to high, depending on part size and complexity

-

Drying Requirements: ABS must be dried at 80–90°C for at least 2–4 hours before processing to avoid moisture bubbles or silver streaks

Processing Temperature Range

Temperature control is critical when molding ABS, as it is sensitive to degradation if overheated.

| Zone | Recommended Temperature |

|---|---|

| Feed Zone | 190 – 210°C |

| Compression Zone | 210 – 230°C |

| Metering Zone | 220 – 250°C |

| Nozzle | 220 – 250°C |

| Mold Temperature | 60 – 80°C |

Maintaining stable and uniform temperature is essential to prevent warping, surface defects, and internal stress.

Injection Pressure & Speed

-

Injection Pressure: 70–120 MPa

-

Holding Pressure: 40–60% of injection pressure

-

Injection Speed: Medium to fast (slower speeds may cause weld lines; faster speeds can help achieve better surface finish)

Shrinkage

ABS has a relatively low shrinkage rate, typically between 0.4% – 0.7% depending on:

-

Wall thickness

-

Mold design

-

Gate type and size

-

Fill rate and pressure

Proper cooling time and uniform mold temperature are crucial to minimize warping and ensure dimensional stability.

Advantages of ABS Injection Molding

ABS is a widely used engineering thermoplastic, especially popular in automotive, Hipanga Kaihoko, and medical device industries. Its combination of mechanical strength, aesthetic quality, and processing ease makes it ideal for injection molding.

1. High Impact Resistance

ABS offers excellent toughness and impact strength, making it suitable for parts that require durability under mechanical stress. This makes it ideal for products like:

-

Protective housings and enclosures

-

Automotive interior components

-

Handheld device cases

Even at low temperatures, ABS maintains impact resistance, making it reliable for both indoor and outdoor applications.

2. Excellent Surface Finish

One of ABS’s standout qualities is its smooth surface finish and good gloss. This allows molded parts to be:

-

Easily painted, plated, or silk-screened

-

Used directly in consumer-facing applications without secondary processing

-

Made with intricate surface details (thanks to its good flow characteristics)

This is why ABS is often used in aesthetic components of electronics, such as remote controls or appliance panels.

3. Recyclability

ABS is a thermoplastic, meaning it can be melted down and reprocessed without significant degradation. Its recyclability offers:

-

Lower material costs through reuse of regrind

-

Reduced environmental impact

-

Easier waste management in high-volume production

Industries increasingly value ABS for sustainable manufacturing due to its recyclability and low VOC emissions.

Nga tono o te werohanga o te riri

He maha nga werohanga a te Abs Winve i roto i nga momo ahumoana, whai wāhi:

- Ahumahi Medical: Nga Hoinga Taputapu, Nga waahanga taputapu tātaritanga

- Aero Aukenga: Papatohu, Ngaro o roto, me nga waahanga bumper

- Hipanga Kaihoko: Ko nga keehi pona, papa papatuhi, me nga mana mamao

- Household Appliances: Vacuum cleaner parts, refrigerator liners, and tool housings

Ko nga tohu whakahiatotanga o te ABF e tino pai ana

he. Tautuhinga pāmahana

Tika Te whakahaere pāmahana te whakarite i te rewa hanga me te aukati i nga ngoikoretanga.

- Te pāmahana paoa: 200-250 ° C (392-482 ° F)

- Te pāmahana o te nonzea: Iti iho i raro i te pāmahana o te paoa hei aukati i te drooling

- Te pāmahana hangarua: 50-80 ° C (122-176 ° F), Kei runga i te matotoru waahanga

pē. Te tere me te pēhanga

- Te pehanga werohanga: 10-20 MPA (1450-2900 psi)

- Pupuri pehanga: 30-50% o te pehanga werohanga

- Tere te werohanga: Waenga i te teitei ki te whakarite kia tika te rere ki roto i nga mekameka hangai

- Pēhanga whakamuri: 0.3-4 MPA te whakarite kia pai te rewa

c. Te wa makariri me te tohetohe

- Te wa makariri: 20-60 hēkona e whakawhirinaki ana ki te matotoru o te waahanga

- Pūnaha Egog: Ko nga waahanga o te abs tika kia pai te whakamatao i mua i te whakawakanga kia kore ai e huri

Nga ngoikoretanga a Bills me nga rongoā

1. Mirumiru me nga riipene hiriwa ranei

- Pūtake: Te nui o te makuku i roto i nga rauemi abs

- Whakamāramatanga: Me whakarite kia maroke tika i mua i te tukatuka

2. Nga tohu

- Pūtake: Te rite na te tere o te werohanga, i te waa noho roa ranei

- Whakamāramatanga: Whakaitihia te pāmahana o te paoa ka whakatika i te tere o te werohanga

3. Poto Poto

- Pūtake: He iti rawa te pehi panu, he pāmahana iti ranei

- Whakamāramatanga: Whakapiki i te pehanga pangau me te whakarite kia pai te pāmahana

4. Uira

- Pūtake: Te pehanga entinger entenahia, he koretake ranei te tohu

- Whakamāramatanga: Whakanohia nga tautuhinga pehanga me te tirotiro i te whakahāngai i te hangai

ABS Injection Molding at XLD Mould

Kei Maeneene Xld, we are committed to delivering high-precision ABS injection molding solutions that meet the most demanding industry standards. Our expertise ensures:

- Custom mold design and engineering for enhanced performance and efficiency

- Material selection guidance to ensure optimal functionality and durability

- Advanced injection molding process optimization to achieve consistent, Nga hua kounga-nui

- Nga rautaki aukati maeneene hei whakaiti i te ururua me te whakanui i te hua

Ma te kaha o to tatou kaha-a-roto-a-toi me te roopu tohunga, Ka hangaia e te XLD te tohu tohu i nga ratonga whakahiato a te AB i hangaia e koe ki o hiahia motuhake.

📞 Whakapaa mai ki a maatau i tenei ra Ki te matapaki i to kaupapa mo te ABB mo te mahi me te tuku i a maatau ki a koe, Nga rongoā paniko.