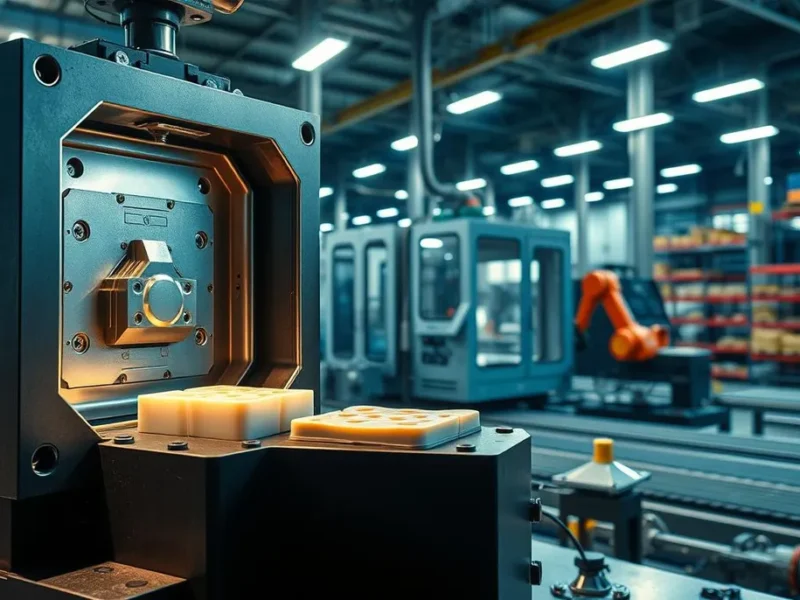

사출 성형 is a crucial manufacturing process used to produce a wide range of plastic products. The longevity of a mold is a significant factor in determining the efficiency and cost-effectiveness of this process.

The lifespan of a mold depends on various factors, including the material used, the design of the mold, and the maintenance practices employed. Understanding these factors is essential to maximize the lifespan of a mold and ensure optimal production.

Effective mold maintenance not only extends injection mold lifespan but also minimizes downtime and costly replacements. Implementing a preventive maintenance program is essential for any high-volume injection molding operation. 이 기사에서는, we will explore the key factors that affect mold lifespan and provide guidance on how to maintain your molds effectively.

Understanding Injection Molds and Their Purpose

At the heart of the 사출 성형 process lies the mold, a sophisticated tool designed to produce high-quality parts. Injection molds are precision-engineered to withstand the rigors of repeated use, making them a crucial component in mass production.

What Is an Injection Mold?

An injection mold is a custom-made tool used to create plastic parts through the injection molding process. It consists of two main parts: the cavity and the core. When combined, these parts form the shape of the desired product.

The Manufacturing Process: How Molds Create Parts

The manufacturing process involves several key steps:

- Melted plastic is injected into the mold cavity.

- The plastic cools and solidifies, taking the shape of the mold.

- The mold opens, and the part is ejected.

- The process is repeated, allowing for high-volume production.

Key Components of an Injection Mold

A typical injection mold consists of several critical components, 포함:

- Cavities and Cores: These form the shape of the final product.

- Runners and Gates: These direct the flow of molten plastic into the mold cavity.

- 배출 시스템: This mechanism pushes the part out of the mold after it has cooled.

- Cooling System: This regulates the temperature of the mold, ensuring efficient production.

Understanding these components is essential for optimizing the injection molding process and producing high-quality parts.

Injection Mold Lifespan: How Many Shots Can an Injection Mold Produce?

The lifespan of an injection mold, measured in shot count, varies significantly based on several factors. Understanding these factors is crucial for manufacturers to optimize production and manage costs effectively.

Shot Count Ranges for Different Mold Classes

Molds are typically classified based on their complexity, 재료, and intended use. 그만큼 shot count range for a mold can vary widely depending on its class. 예를 들어:

- Prototype molds are designed for low-volume production and may last for a few hundred shots.

- Production molds, 반면에, are built for durability and can last for hundreds of thousands of shots.

Industry Benchmarks and Standards

Industry benchmarks for mold lifespan are influenced by factors such as mold material, 부분 복잡성, and processing conditions. While there’s no one-size-fits-all answer, certain standards have been established:

- A well-maintained steel mold can achieve a lifespan of 500,000 에게 1,000,000 shots or more.

- Aluminum molds, while less durable, can still provide a significant number of shots, typically in the range of 10,000 에게 100,000.

Realistic Expectations for Various Applications

For different applications, the expected mold lifespan can vary significantly. For example:

- Molds used in the production of high-precision parts may have a shorter lifespan due to the stringent quality requirements.

- Molds for high-volume consumer goods are designed to maximize production efficiency and lifespan.

By understanding these factors and benchmarks, manufacturers can set realistic expectations for their mold lifespan and plan accordingly.

Types of Molds and Their Durability

Understanding the different types of molds is crucial for determining their durability and maintenance needs. Injection molds are categorized based on their design, 기능, and application, each type having a distinct impact on its lifespan.

Prototype vs. Production Molds

Prototype molds are designed for testing and validating part designs before mass production. They are typically made with less durable materials and have a shorter lifespan, often used for a limited number of shots. In contrast, production molds are built for longevity and high-volume production, using robust materials that can withstand hundreds of thousands of shots.

The choice between prototype and production molds depends on the stage of product development and the required production volume. Prototype molds offer flexibility and cost savings during the initial stages, while production molds are optimized for efficiency and durability.

Family Molds vs. Single Cavity Molds

Family molds are designed to produce multiple parts or variations within a single mold, offering advantages in terms of production efficiency and cost savings. 하지만, they can be more complex and may have a shorter lifespan due to the increased complexity and potential for wear across multiple cavities.

Single cavity molds, 반면에, are dedicated to producing a single part, allowing for simpler design and potentially longer lifespan. The choice between family and single cavity molds depends on production requirements and part complexity.

Hot Runner vs. Cold Runner Systems

Hot runner systems maintain the plastic material in a molten state within the mold, reducing waste and cycle times. While they offer significant production advantages, hot runner systems can be more complex and may require more maintenance, potentially affecting mold durability.

Cold runner systems, by contrast, allow the runner to solidify and be ejected with the part, simplifying mold design but potentially increasing material waste. The choice between hot and cold runner systems impacts not only production efficiency but also mold longevity.

Mold Materials and Their Impact on Longevity

Mold materials play a crucial role in determining the lifespan and performance of injection molds. The choice of material affects not only the mold’s durability but also its production efficiency and the quality of the parts it produces.

Aluminum Molds: Benefits and Limitations

Aluminum molds are favored for their excellent thermal conductivity, which allows for faster cycle times and improved part quality. 하지만, they have limitations in terms of durability and are generally used for low to medium volume production or for creating prototype parts.

Steel Grades: P20, H13, S7, and More

Steel is the most common material used for injection molds due to its high durability and ability to withstand the pressures of high-volume production. Different steel grades, such as P20, H13, and S7, offer varying levels of hardness, 강인함, and resistance to wear and corrosion, making them suitable for a wide range of applications.

Beryllium Copper and Other Specialty Materials

Beryllium copper is a specialty material used in molds for its high thermal conductivity and strength. It’s particularly useful in applications requiring rapid cooling and high precision. Other specialty materials are also used to address specific production challenges, such as corrosive environments or high-temperature applications.

The selection of mold material is a critical decision that impacts the overall efficiency, 비용, and quality of the injection molding process. By understanding the properties and applications of different mold materials, manufacturers can make informed decisions to optimize their production processes.

Factors That Affect Mold Wear and Deterioration

The longevity of an injection mold depends on several key factors. Understanding these elements is crucial for manufacturers to optimize their molding processes and extend the life of their molds.

Part Geometry and Complexity

The design and complexity of the parts being molded significantly impact mold wear. Parts with intricate geometries or sharp corners can cause uneven stress distribution on the mold, leading to increased wear in specific areas. Complex geometries often require more sophisticated mold designs, which can be more prone to damage if not properly maintained.

Processing Parameters and Cycle Times

Processing parameters such as temperature, 압력, and cycle time play a critical role in mold wear. Higher temperatures and pressures can accelerate wear, especially if the mold material is not suited for the operating conditions. Optimizing cycle times without compromising part quality is a delicate balance that can help reduce wear.

Machine Maintenance and Operator Skill

The condition of the injection molding machine and the skill level of the operator are also significant factors. Regular machine maintenance ensures that the mold is subjected to consistent and appropriate operating conditions. Well-trained operators can identify potential issues before they become major problems, thereby reducing the risk of mold damage.

Clamping Force Considerations

Inadequate or excessive clamping force can lead to mold wear. Insufficient clamping force may result in flash, while too much force can cause excessive stress on the mold, potentially leading to deformation or damage.

Injection Pressure Effects

Injection pressure is another critical factor. High injection pressures can cause the mold to be over-stressed, leading to wear and potentially even mold failure. The pressure should be optimized based on the material being molded and the part design.

| Factor | Impact on Mold Wear | Mitigation Strategy |

| Part Geometry | Complex geometries increase wear | Optimize part design for simplicity |

| Processing Parameters | High temps and pressures accelerate wear | Adjust parameters to optimal levels |

| Machine Maintenance | Poor maintenance increases risk of damage | Regularly maintain equipment |

“The key to extending mold life lies in understanding the interplay between part design, 처리 조건, and machine maintenance. By optimizing these factors, manufacturers can significantly reduce mold wear and improve overall efficiency.”

How Plastic Materials Impact Mold Life

Plastic materials play a crucial role in determining the durability and longevity of molds in injection molding processes. The characteristics of these materials can significantly affect how long a mold lasts and how well it performs over time.

Abrasive Materials: Glass and Mineral Fillers

Abrasive materials, such as glass and mineral fillers, can cause significant wear on mold surfaces. These materials are often added to plastics to enhance their strength and durability, but they can lead to increased erosion of the mold’s surface, reducing its lifespan. Regular maintenance is crucial when working with such materials to mitigate their abrasive effects.

Corrosive Materials and Chemical Reactions

Some plastic materials are corrosive and can react with the mold’s surface, leading to degradation over time. This is particularly true for materials that contain certain chemicals or additives. Selecting the right mold material that is resistant to these corrosive effects is essential for maintaining mold integrity.

High-Temperature Resins and Thermal Stress

High-temperature resins can cause thermal stress to the mold, potentially leading to cracks and other forms of damage. These resins require molds that can withstand extreme temperatures without losing their shape or structural integrity.

“The right mold steel can make all the difference when working with high-temperature materials.”

Using high-quality, heat-resistant materials for the mold can help extend its lifespan.

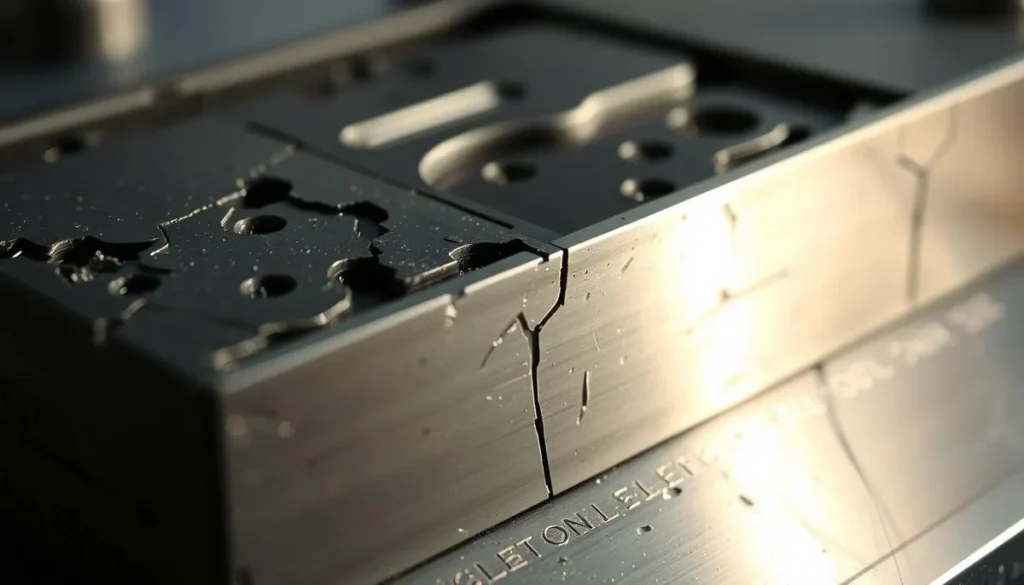

Identifying Signs of Mold Wear and Damage

Monitoring the condition of your tooling is essential to spot early signs of mold wear and damage, which can significantly reduce injection mold lifespan if not addressed promptly. Mold wear can lead to decreased product quality and increased production costs. Therefore, it’s essential to monitor molds regularly for signs of deterioration.

Visual Indicators on Mold Surfaces

Visual inspection is the first step in identifying mold wear. Look for signs such as scratches, rust, or corrosion on the mold surface. These can indicate that the mold is deteriorating and may need maintenance or replacement.

Part Quality Issues That Signal Problems

Changes in part quality can also signal mold wear. Issues such as warping, flash, or dimensional inconsistencies may indicate that the mold is no longer functioning correctly.

Performance Metrics to Monitor

Monitoring performance metrics is crucial for early detection of mold wear. Key metrics include:

Cycle Time Increases

An increase in cycle time can indicate that the mold is experiencing wear or damage, affecting production efficiency.

Pressure Requirement Changes

Changes in pressure requirements can also signal mold wear. Increased pressure may be needed to achieve the desired part quality, indicating potential issues with the mold.

| Signs of Mold Wear | Description | Potential Impact |

| Visual Damage | Scratches, rust, or corrosion on mold surface | Decreased part quality, potential mold failure |

| Part Quality Issues | Warping, flash, or dimensional inconsistencies | Increased scrap rates, production delays |

| Performance Metric Changes | Increased cycle times, changes in pressure requirements | Reduced production efficiency, increased costs |

Essential Preventive Maintenance Practices

To maximize mold performance and longevity, a well-structured preventive maintenance program is essential. This proactive approach helps in identifying potential issues before they become major problems, thereby reducing downtime and improving overall production efficiency.

Developing Effective Maintenance Schedules

Creating a maintenance schedule involves understanding the mold’s usage patterns, material specifications, and the manufacturing environment. Regular inspections and maintenance tasks should be scheduled based on the number of shots or production cycles.

Cleaning Procedures and Best Practices

Cleaning is a critical aspect of mold maintenance best practices, ensuring your injection molds last longer and remain cost-efficient. It’s essential to use appropriate cleaning methods and materials that won’t damage the mold surfaces. Soft brushes and mild cleaning solutions are often recommended.

Lubrication Requirements and Frequency

Proper lubrication is vital for the smooth operation of mold components. The type and frequency of lubrication depend on the mold design and the materials being processed.

Recommended Lubricants by Application

- Molybdenum disulfide for high-temperature applications

- Silicone-based lubricants for general use

Documentation Systems

Maintaining detailed records of maintenance activities is crucial. This includes documenting cleaning schedules, lubrication records, and any repairs or replacements made.

By implementing these preventive maintenance practices, manufacturers can significantly extend the lifespan of their molds, reduce production costs, and improve product quality.

Troubleshooting Common Mold Issues

Effective troubleshooting is key to resolving mold-related issues. Mold maintenance involves identifying and addressing common problems promptly to minimize production downtime.

Sticking Parts and Ejection Problems

Sticking parts can be caused by inadequate ejection or excessive part shrinkage. Ensuring proper ejection pin maintenance and adjusting mold release parameters can mitigate these issues.

Flash and Dimensional Issues

Flash occurs when melted plastic seeps into the mold’s parting line. This can be due to worn-out molds 또는 improper clamping. Dimensional issues often result from inconsistent cooling or incorrect mold design.

Venting Problems and Gas Traps

Inadequate venting can cause gas traps, leading to part defects. Proper venting design and regular cleaning are essential for preventing these issues.

Cooling System Maintenance

A well-maintained cooling system is crucial for consistent part quality. Regularly inspect and clean cooling channels to prevent clogging and ensure efficient heat transfer.

| Issue | 원인 | 해결책 |

| Sticking Parts | Inadequate ejection, part shrinkage | Maintain ejection pins, adjust mold release |

| Flash | Worn-out molds, improper clamping | Replace molds, adjust clamping force |

| Venting Problems | Inadequate venting design | Improve venting design, regular cleaning |

Extending Mold Life Through Proper andling

Proper mold handling is crucial for maximizing the lifespan of injection molds. Effective handling practices not only reduce wear and tear but also ensure that molds perform optimally throughout their service life.

Storage Best Practices

When not in use, molds should be stored in a dry, clean environment. Proper storage involves protecting molds from dust, moisture, and physical damage. It’s advisable to store molds in a dedicated area, away from direct sunlight and extreme temperatures.

사용 desiccants or dehumidifiers can help maintain a stable humidity level, preventing rust and corrosion on metal surfaces.

| Storage Condition | Benefit |

| Dry Environment | Prevents Rust and Corrosion |

| Cleanliness | Reduces Contamination Risk |

| Controlled Temperature | Maintains Mold Integrity |

Transportation and Installation Procedures

During transportation, molds should be securely fastened to prevent movement or impact damage. Proper lifting techniques should be used to avoid straining or dropping the mold.

Upon installation, it’s crucial to follow the manufacturer’s guidelines to ensure that the mold is correctly seated and aligned.

Training Requirements for Mold Handlers

Personnel involved in handling molds should undergo comprehensive training. This includes understanding mold design specifics, handling techniques, and safety protocols.

Regular training updates can help handlers stay informed about best practices and new technologies.

Repair, Refurbishment, and Replacement Decisions

Understanding when to repair, refurbish, or replace a mold can greatly impact production costs and quality. The decision-making process involves evaluating the mold’s condition, considering the cost of repairs, and assessing the impact on production.

When to Repair vs. When to Replace

Determining whether to repair or replace a mold depends on several factors, including the extent of the damage, the mold’s age, and its overall condition. Minor issues such as worn-out ejector pins or slight surface damage can often be repaired, extending the mold’s lifespan. 하지만, if the mold is old or has significant structural damage, replacement might be more cost-effective.

- Assess the mold’s condition thoroughly

- Consider the cost of repairs versus replacement

- Evaluate the impact on production quality and efficiency

Common Repair Techniques and Technologies

Modern mold repair techniques include welding, machining, and surface treatment. Advanced technologies like 3D printing are also being used to repair complex molds. The choice of repair technique depends on the type of damage and the materials involved.

Finding Qualified Mold Repair Services

To ensure high-quality repairs, it’s crucial to find experienced and skilled mold repair services. Look for providers with a proven track record, advanced equipment, and a thorough understanding of mold design and manufacturing.

Cost-Benefit Analysis of Repairs

Conducting a cost-benefit analysis is essential to decide whether to repair or replace a mold. This involves calculating the cost of repairs, the potential extension of the mold’s lifespan, and the impact on production costs and quality.

- Calculate the cost of repairs

- Assess the potential extension of the mold’s lifespan

- Evaluate the impact on production costs and quality

By carefully considering these factors, manufacturers can make informed decisions that optimize their mold maintenance budget and ensure uninterrupted production.

결론: Maximizing Your Mold Investment

Proper maintenance and handling practices are crucial to maximizing your mold investment. By understanding the factors that affect mold lifespan and implementing effective maintenance practices, you can significantly extend the life of your molds.

Regular cleaning, lubrication, and inspection can help prevent wear and deterioration. 또한, proper storage and transportation procedures can reduce the risk of damage. By following these best practices, you can ensure your molds continue to produce high-quality parts and maximize your return on investment.

Maximizing mold investment requires a proactive approach to maintenance and handling. By prioritizing these practices, you can optimize mold performance, reduce downtime, and increase overall productivity. Effective maintenance practices play a critical role in achieving these goals and ensuring the longevity of your molds.

Need Help with Mold Maintenance or Manufacturing?

At XLD Mould, we specialize in high-precision injection molds and provide expert mold maintenance services. Contact us today to optimize your mold performance and reduce downtime.

8k0f10

xfu6sq

hi!,I like your writing so a lot! percentage we communicate more approximately your post on AOL? I need an expert on this space to resolve my problem. Maybe that is you! Having a look forward to see you.

gvfnd7

I genuinely enjoy examining on this website , it has got fantastic blog posts.

Sweet blog! I found it while surfing around on Yahoo News. Do you have any suggestions on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Appreciate it

It’s exhausting to seek out educated folks on this subject, however you sound like you already know what you’re speaking about! Thanks

Loving the info on this web site, you have done outstanding job on the articles.

I like the efforts you have put in this, appreciate it for all the great content.

I haven’t checked in here for some time since I thought it was getting boring, but the last several posts are good quality so I guess I will add you back to my everyday bloglist. You deserve it my friend 🙂

F*ckin’ remarkable issues here. I am very glad to peer your post. Thanks a lot and i am taking a look ahead to touch you. Will you please drop me a mail?

I’ve recently started a website, the information you provide on this site has helped me greatly. Thanks for all of your time & work. “The achievements of an organization are the results of the combined effort of each individual.” by Vince Lombardi.

You have observed very interesting points! ps decent website.

Wohh just what I was searching for, thanks for posting.

I truly appreciate your work, Great post.

I was looking through some of your blog posts on this site and I believe this website is rattling informative! Keep posting.

I’m not sure why but this blog is loading incredibly slow for me. Is anyone else having this issue or is it a problem on my end? I’ll check back later and see if the problem still exists.

There are certainly a whole lot of particulars like that to take into consideration. That could be a nice level to convey up. I provide the ideas above as general inspiration but clearly there are questions like the one you carry up the place crucial factor might be working in sincere good faith. I don?t know if best practices have emerged around issues like that, but I’m certain that your job is clearly recognized as a good game. Each girls and boys feel the impact of just a second’s pleasure, for the rest of their lives.

Wow! Thank you! I constantly needed to write on my website something like that. Can I implement a portion of your post to my blog?

I have been exploring for a bit for any high quality articles or weblog posts on this kind of area . Exploring in Yahoo I eventually stumbled upon this site. Studying this info So i’m happy to convey that I have a very excellent uncanny feeling I found out just what I needed. I most definitely will make certain to do not fail to remember this web site and give it a look on a relentless basis.

Its good as your other articles : D, appreciate it for putting up.

I dugg some of you post as I cerebrated they were invaluable handy

Thanks , I’ve just been looking for information about this subject for a while and yours is the greatest I have found out so far. 하지만, what concerning the conclusion? Are you positive concerning the source?

I carry on listening to the rumor speak about getting free online grant applications so I have been looking around for the best site to get one. Could you advise me please, where could i acquire some?

Good day! Would you mind if I share your blog with my zynga group? There’s a lot of folks that I think would really appreciate your content. Please let me know. Cheers

I conceive this internet site holds very superb pent written content blog posts.

Today, I went to the beach front with my kids. I found a sea shell and gave it to my 4 year old daughter and said “You can hear the ocean if you put this to your ear.” She put the shell to her ear and screamed. There was a hermit crab inside and it pinched her ear. She never wants to go back! LoL I know this is completely off topic but I had to tell someone!

Sweet blog! I found it while browsing on Yahoo News. Do you have any suggestions on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Thank you

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.

Of course, what a magnificent site and illuminating posts, I will bookmark your site.Best Regards!

Hello. impressive job. I did not imagine this. This is a remarkable story. Thanks!

Undeniably believe that which you stated. Your favorite reason appeared to be on the internet the simplest thing to be aware of. I say to you, I certainly get irked while people consider worries that they plainly don’t know about. You managed to hit the nail upon the top and defined out the whole thing without having side effect , people can take a signal. Will likely be back to get more. Thanks

I’ve been absent for a while, but now I remember why I used to love this blog. Thanks, I will try and check back more frequently. How frequently you update your website?

superb post.Never knew this, regards for letting me know.

That is really interesting, You’re an excessively skilled blogger. I have joined your rss feed and look ahead to looking for extra of your magnificent post. 또한, I have shared your web site in my social networks!

There is noticeably a bundle to know about this. I assume you made certain nice points in features also.

I used to be recommended this website by means of my cousin. I am not sure whether or not this post is written by means of him as nobody else recognize such targeted approximately my problem. You’re incredible! Thank you!

Simply a smiling visitant here to share the love (:, btw outstanding design. “The price one pays for pursuing a profession, or calling, is an intimate knowledge of its ugly side.” by James Arthur Baldwin.

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.

Pretty great post. I simply stumbled upon your blog and wanted to say that I’ve truly loved browsing your weblog posts. In any case I’ll be subscribing to your feed and I hope you write again soon!

I like this site so much, saved to fav.

Just desire to say your article is as astounding. The clearness for your put up is simply excellent and i can think you are knowledgeable on this subject. Fine with your permission let me to snatch your feed to stay up to date with coming near near post. Thank you one million and please keep up the rewarding work.

Hello! I just would like to give a huge thumbs up for the great info you have here on this post. I will be coming back to your blog for more soon.

Howdy just wanted to give you a brief heads up and let you know a few of the images aren’t loading properly. I’m not sure why but I think its a linking issue. I’ve tried it in two different web browsers and both show the same outcome.

This blog is definitely rather handy since I’m at the moment creating an internet floral website – although I am only starting out therefore it’s really fairly small, nothing like this site. Can link to a few of the posts here as they are quite. Thanks much. Zoey Olsen

As a Newbie, I am continuously exploring online for articles that can help me. Thank you

Only a smiling visitant here to share the love (:, btw outstanding design and style. “Competition is a painful thing, but it produces great results.” by Jerry Flint.

I’m really enjoying the design and layout of your blog. It’s a very easy on the eyes which makes it much more pleasant for me to come here and visit more often. Did you hire out a developer to create your theme? Excellent work!

Would you be all for exchanging links?

iXOzuGDlvQNqpFyLsjSeazF

You completed certain fine points there. I did a search on the subject and found nearly all people will have the same opinion with your blog.

Unquestionably believe that which you stated. Your favorite justification seemed to be on the web the simplest thing to be aware of. I say to you, I definitely get irked while people consider worries that they just do not know about. You managed to hit the nail upon the top and defined out the whole thing without having side-effects , people can take a signal. Will likely be back to get more. Thanks

I like the valuable info you provide in your articles. I will bookmark your weblog and check again here frequently. I’m quite sure I’ll learn lots of new stuff right here! Best of luck for the next!

I am not real superb with English but I come up this really leisurely to translate.

Simply want to say your article is as astounding. The clarity in your post is simply excellent and that i could suppose you’re knowledgeable in this subject. Well along with your permission allow me to grab your feed to stay up to date with imminent post. Thanks a million and please keep up the rewarding work.

Hi! I just wanted to ask if you ever have any problems with hackers? My last blog (wordpress) was hacked and I ended up losing a few months of hard work due to no back up. Do you have any methods to prevent hackers?

Very interesting information!Perfect just what I was looking for! “The right to be heard does not autmatically include the right to be taken seriously.” by Hubert Humphrey.

Perfectly pent subject matter, appreciate it for information .

I’m still learning from you, as I’m making my way to the top as well. I certainly enjoy reading everything that is written on your site.Keep the information coming. I loved it!

Yo, the td777gameapk is pretty solid overall! Downloaded it last night and now I’m low-key hooked on it. Game selection is cool! td777gameapk

Wow! Thank you! I continuously wanted to write on my website something like that. Can I include a part of your post to my site?

I got good info from your blog

I appreciate, cause I found exactly what I was looking for. You have ended my four day long hunt! God Bless you man. Have a great day. Bye

Thank you for the sensible critique. Me and my neighbor were just preparing to do a little research on this. We got a grab a book from our local library but I think I learned more from this post. I am very glad to see such great info being shared freely out there.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/uk-UA/register?ref=XZNNWTW7

Found everything I needed about Bong88 at bong88bio.net. Good platform for info and links. See for yourself: bong88bio

Great write-up, I¦m regular visitor of one¦s website, maintain up the excellent operate, and It is going to be a regular visitor for a long time.

Wow! This could be one particular of the most helpful blogs We’ve ever arrive across on this subject. Actually Wonderful. I am also an expert in this topic so I can understand your effort.

You made some first rate factors there. I seemed on the web for the difficulty and located most individuals will go along with with your website.

magnificent issues altogether, you simply won a logo new reader. What might you recommend in regards to your submit that you just made a few days ago? Any certain?

Of course, what a fantastic website and enlightening posts, I will bookmark your blog.All the Best!

Im not certain where you’re getting your information, however great topic. I needs to spend some time finding out much more or understanding more. Thank you for magnificent information I used to be looking for this information for my mission.

Only wanna comment on few general things, The website pattern is perfect, the content is real good : D.

Some genuinely prize posts on this website , saved to favorites.

I rattling pleased to find this web site on bing, just what I was looking for : D too saved to bookmarks.

I conceive this website contains some really excellent information for everyone. “I prefer the wicked rather than the foolish. The wicked sometimes rest.” by Alexandre Dumas.

Saved as a favorite, I really like your blog!

I appreciate, cause I found exactly what I was looking for. You have ended my 4 day long hunt! God Bless you man. Have a nice day. Bye

Good – I should certainly pronounce, impressed with your site. I had no trouble navigating through all the tabs and related information ended up being truly simple to do to access. I recently found what I hoped for before you know it in the least. Quite unusual. Is likely to appreciate it for those who add forums or anything, web site theme . a tones way for your client to communicate. Nice task.

My brother recommended I might like this website. He was totally right. This post truly made my day. You cann’t imagine just how much time I had spent for this information! Thanks!

What’s Going down i’m new to this, I stumbled upon this I’ve found It positively useful and it has aided me out loads. I am hoping to give a contribution & aid other users like its helped me. Great job.

I’d must verify with you here. Which is not one thing I often do! I take pleasure in reading a publish that may make people think. 또한, thanks for allowing me to comment!

Hey There. I found your blog using msn. This is an extremely well written article. I will make sure to bookmark it and return to read more of your useful information. Thanks for the post. I will certainly return.

I’m not sure why but this blog is loading very slow for me. Is anyone else having this problem or is it a issue on my end? I’ll check back later on and see if the problem still exists.

I’ve been browsing on-line greater than three hours these days, yet I by no means found any fascinating article like yours. It¦s pretty value enough for me. In my view, if all website owners and bloggers made just right content as you probably did, the net shall be a lot more helpful than ever before.

Outstanding post, you have pointed out some good points, I too believe this s a very great website.

Hi my friend! I want to say that this article is amazing, great written and come with approximately all important infos. I would like to peer more posts like this .

Hello, you used to write wonderful, but the last few posts have been kinda boring?K I miss your great writings. Past several posts are just a little bit out of track! come on!

Hello there! This is my first visit to your blog! We are a team of volunteers and starting a new project in a community in the same niche. Your blog provided us valuable information to work on. You have done a wonderful job!

Real informative and excellent complex body part of subject matter, now that’s user pleasant (:.

you have a terrific weblog here! would you like to make some invite posts on my blog?

I regard something truly interesting about your web site so I saved to fav.

Been hearing some buzz about 6566bet1. Supposedly they have some exclusive slots. Gonna create an account and see if it’s worth the hype.

Thanks – Enjoyed this article, how can I make is so that I get an update sent in an email when there is a fresh post?

I will right away grab your rss as I can’t in finding your e-mail subscription link or newsletter service. Do you have any? Kindly allow me realize so that I may subscribe. Thanks.

I am sure this piece of writing has touched all the internet people, its really really nice paragraph on building up new web site.

I’ll immediately grab your rss feed as I can’t to find your e-mail subscription hyperlink or newsletter service. Do you’ve any? Please permit me understand in order that I could subscribe. Thanks.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. 하지만, I have a question, can you help me?

You have noted very interesting details! ps nice internet site. “The empires of the future are the empires of the mind.” by Sir Winston Leonard Spenser Churchill.

We’re a group of volunteers and opening a new scheme in our community. Your site offered us with valuable info to work on. You have done an impressive job and our entire community will be grateful to you.

Sweet blog! I found it while searching on Yahoo News. Do you have any suggestions on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Many thanks

Hi my family member! I wish to say that this post is awesome, nice written and include almost all significant infos. I’d like to see extra posts like this.

You made some first rate factors there. I seemed on the web for the difficulty and located most people will associate with together with your website.

It’s actually a cool and useful piece of info. I’m glad that you shared this useful information with us. Please keep us up to date like this. Thanks for sharing.

I like what you guys are up also. Such intelligent work and reporting! Keep up the excellent works guys I have incorporated you guys to my blogroll. I think it will improve the value of my site 🙂

I like what you guys are up too. Such clever work and reporting! Carry on the superb works guys I¦ve incorporated you guys to my blogroll. I think it’ll improve the value of my web site 🙂

I believe this website contains some very good info for everyone. “The expert at anything was once a beginner.” by Hayes.

I have been examinating out a few of your posts and it’s clever stuff. I will surely bookmark your website.

Hi there, I found your site by way of Google at the same time as looking for a related topic, your web site came up, it looks great. I’ve bookmarked it in my google bookmarks.

Loving the info on this web site, you have done great job on the posts.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.